Comparing the Winn Speed Lock Vise to the Kurt Vise

Since coming out with the Winn Speed Lock 6″ Vise a few years ago, I am asked on a regular basis how the Winn Speedlock compares to the Kurt vises. To begin with Kurt makes an excellent product and has for a long time. As a matter of fact, one of the challenges I have with sales, is that the Kurt product doesn’t really wear out, so shops aren’t looking to replace worn out vises as much as they are looking to purchase because of additional needs. One of my primary goals was to make a quality vise that would compare in quality and durability to a 6″ Kurt vise but also include numerous time saving benefits and still remain at a substantially lower cost.

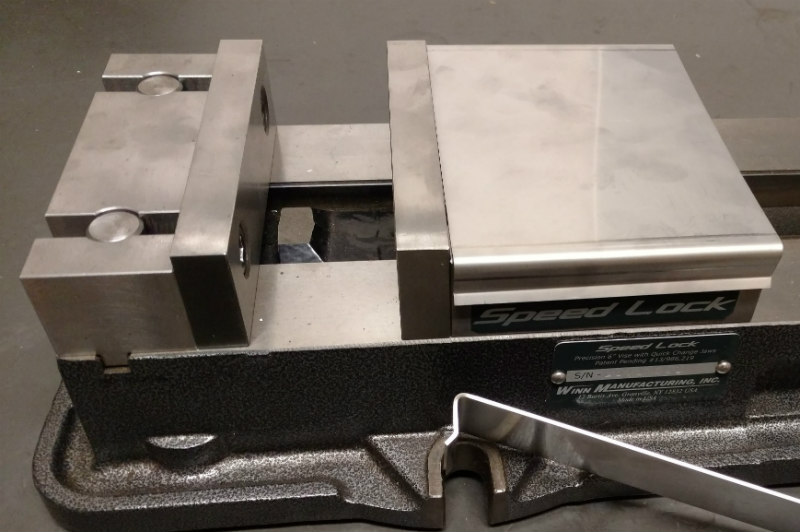

High Quality and Long Lasting 6” Vise

The Winn Speed Lock Vise is a high quality, reliable product that shops will own and use for an extended period of time. It is an angle lock design, has a flame hardened bed and is American made.

How does Winn Speedlock Save Time and Money over the Kurt Vise?

Besides, saving your company substantial money, (cost comparison) the key feature that makes the Winn Speed Lock Vise different from the Kurt Vise is that the Winn Speedlock has an integrated quick change jaw system. This feature allows the user to change the vise jaws in 30 seconds or less. The Kurt has the DoveLock system, but this is an add on to their vise and is not integrated to the vise. Additionally, because the Winn Speed Lock Vise system is built into the mounting blocks, this means that there is no loss of the 8″ opening size of the vise. The Kurt DoveLock system requires a 3/4 inch thick master jaw be bolted to the inside of the mounting blocks. This will reduce the opening size of the Kurt vise by 1-1/2 inches. Also, if a shop has already built a custom set of vise jaws for a job, before they purchased the DoveLock system, either the master jaws need to be removed to put the standard bolt pattern jaws on the vise or a new set needs to be made with the special DoveLock aluminum jaw stock that has to be purchased from Kurt. This is not a time saver.

Winn Speedlock Vise – Inside to Outside Mounting in 30 Seconds

The Kurt DoveLock system was never designed to be used on the outside of the mounting blocks, so if you have this system on a vise and need to put jaws on the outside of the mounting blocks, you either need to remove the masters jaws from the vise and put them back on when your done or remove the vise from the machine and mount a vise onto the machine that doesn’t have the “quick change” installed on it, and then unbolt the vise jaws from the inside and bolt them onto the outside. ( Hopefully, when the vise was put away someone cleaned out the tapped holes in the mounting blocks, so the bolts go in okay.) Another real timesaver.

With the Winn Speed Lock Vise integrated quick change jaw system, you simply move the vise jaws from the inside to the outside of the mounting blocks in about 30 seconds and move on to getting your work done, instead of changing master jaws or mounting a different vise on the machine to do the job you need to get out.

Designed for Easy Maintenance and Longevity

Another feature of the Winn Speed Lock Vise that is different from Kurt’s and most other vises, is the holes and slots that accept the round nuts that are attached to the vise jaws. With most other vises, there is a 1/2-13 tapped hole to bolt the jaws onto the vise. A lot of machinists will shorten the bolts used to attach the jaws in order to reduce the time it takes to screw the bolts into the jaws on the vise. If they over torque them, it will strip out or damage the threads, which means that the vise will need to be repaired or at least have the 1/2-13 holes re-tapped. From my experience this usually has to be done when you are in a hurry or trying to get a part or fixture done while someone is waiting. Because the Winn Speed Lock Vise system uses a round nut that is attached to the vise jaw, even if it gets over torqued, it is less likely to strip or damage the threads, because it has the recommended thread engagement of 1-1/2 time the thread diameter. But if it does get ruined, it can be simply replaced, because each vise comes with extra sets.

Another question that I have been asked is, “ Do the chips from machining built up in the slots where the round nut assembly drops into the mounting blocks?” The answer to this question is yes, but that they simply blow out with compressed air. We also have covers that can snap over the mounting blocks, these stainless steel covers keep the chips out of the holes and slots in the mountings blocks. With both the Kurt DoveLock system and the Cravesmart system, they use (3) wedges on each jaw, that use a 5/32 hex key wrench to lock the jaws into place. When the small chips get into these and if you can’t get the small 5/32 hex wrench into the lock screws in the wedges, then you can’t get the quick change jaws out. With the Winn Speed Lock system, the jaws are locked in place with a large 3/8 hex wrench, that even if the chips are packed into the slots, the jaws can be removed by using the wrench as a handle and lifting them up and out.

Less cost, quick change jaws, no loss of opening size and easy maintenance are just a few of the benefits of purchasing a Winn Speedlock vise compared to the Kurt Dovelock Vise. If you would like to see how to save money and time compared to the other vises like the Fastback, CarveSmart, J-Loc or Snap Jaws, please see the comparison chart.

I am sure that there are a few questions that I didn’t answer in this blog. Please go to our website at www.winnspeedlock.com and check out the features of the Winn Speed Lock 6″ Vise. I invite you to go to the contact page and ask us any questions about the features of the vise and we will quickly respond to your questions.