Winn Manufacturing shares a CNC machine setup challenge – and a cost-saving solution.

Winn Manufacturing has three CNC lathes. Two are older Cincinnati CNC machines that have been retrofitted with new controls. The other is a Methods Slant 50 CNC turning center from the 1990s. All three CNC lathes have turrets with multiple tool stations. These tool holders can accommodate square turning tools or conventional mounting blocks that hold round tools.

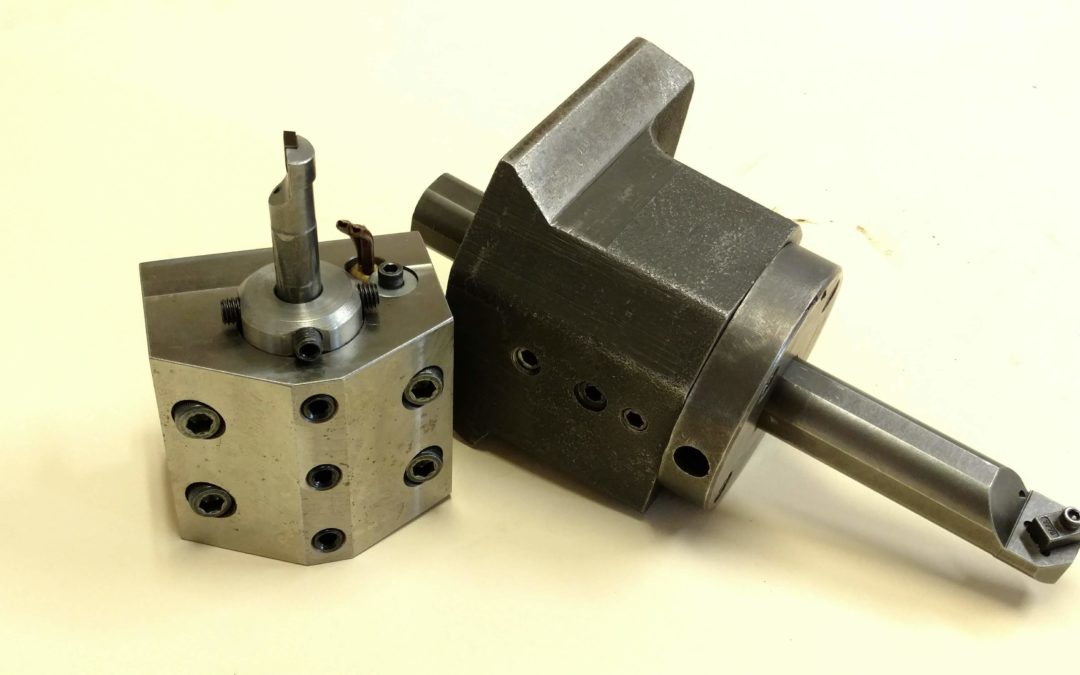

The square turning tools are easy-to-change. The round bars and drills that attach to the conventional blocks are a different story. These mounting blocks vary by lathe type, too. The Slant 50 block attaches to the tool turret with (4) 12MM bolts. The blocks for the Cincinnati machines have a dovetail with a large clamp for turret mounting.

With square tooling, our CNC tool changes take little time and effort. With round tools, the problems start during mounting. Conventional blocks have over-sized holes so that adapter sleeves or bushings can accommodate round tools in various sizes. The bars and drills are held in place with set screws, a standard setup for older equipment.

When CNC lathe tools have been in mounting blocks for an extended period of time, the set screws fill with chips, coolant, dirt, and rust. This makes it difficult to insert a hex key and loosen them. Dirt that gets packed between the boring bars, sleeves, and mounting block can also “cement” the sleeves and tooling into the mounting blocks.

At Winn Manufacturing, we’ve used a press to remove the boring bars and sleeves after all of the set screws are loose. Depending on the difficulty of these CNC tool changes, we’ve spent between 45 minutes to an hour disassembling a block. That’s way too long for job changeovers at a busy machine shop like ours – or yours.

To address this problem, Winn Manufacturing purchased or made enough mounting blocks to keep all of our round tools setup all of the time. (Most of our drills and boring bars cross-over from part to part.) This lets us swap-out mounting blocks in the lathe turrets instead of spending time on individual tool changes. It’s a solution that works most of the time, but there are exceptions.

Recently, Winn Manufacturing saw the end of a job that had required a dedicated tooling setup since 2005. There were three mounting blocks that needed to be broken down and made available for other tooling. After spending 13 years with a single setup, we spent a long afternoon tearing down the blocks, cleaning them, and installing new tooling.

There’s always a cost to buying or making tooling for CNC machines, but this example shows how speeding up CNC tool changes can provide a return on investment. There’s also a payoff from keeping CNC machines running and employees working on jobs instead of tearing down tool blocks. These cost-saving benefits are what’s behind the design of the Winn Speed Lock Vise quick-change jaw system.

Simplifying CNC machine setups saves you time and money. It makes no difference if the majority of your CNC turning and milling work is repeat jobs, or if you machine different parts every time. Plus, your customers (and mine) have reduced their inventories over the past years. They’re constantly asking for shorter lead times and smaller lot sizes. Are you ready for the challenge?

By reducing changeover times, you can reduce your lead times and get parts out the door faster. To learn more about the benefits of the Winn Speed Lock Vise, contact us.

Thanks for the comment about CNC machining. My brother is planning on opening a machining shop soon. Maybe he would like to know how to go faster with projects.